It’s more than just artificial grass.

Turf Types

Have you ever stood on artificial turf?

Did you stop to think about what manufacturing synthetic turf involves?

It’s OK if you haven’t. Most of us probably haven’t.

But, if you want to learn more, we have our guide for you. Turf can be created with many materials such as nylon, polyester, or combinations of both.

Check out this comparison guide to get the pros and cons of each type of fiber.

NYLON

Pros

- While denier and yarn composition affect durability, nylon is usually stronger when compared directly.

Cons

- More vulnerable to expansion and contraction.

- Will fade with direct sunlight exposure.

POLYESTER

Pros

- Less vulnerable to expansion and contraction.

- Polyester is less susceptible to UV than nylon.

Cons

- Less durable than nylon per pound.

NYLON & POLYESTER

Pros

- Has water-resistant properties.

- Less likely to tear.

- Resistant to saltwater corrosion and mildew.

Cons

- Nylon and Polyester are flammable. However, each reacts differently to fire; nylon melts before it burns, polyester melts before it burns.

It’s Not Only About Fiber

There are numerous artificial grass companies out there marketing their products. But, we want to let you in on a little secret. One of the most essential elements of synthetic grass is not only the source of the fiber (grass blades) is made from. The turf is a system that has to be implemented correctly for optimal performance. Below are just a few elements that establish a low-quality synthetic turf from a high-quality turf.

BACKING

The backing is comprised of two layers and finished with a urethane coating. These items are critical as they hold the fibers (grass blades) in place, allow water to flow through, and stand up to abrasion from the base material.

INFILL

Infill is a vital component. It adds labor and time but it is the final touch that ensures your warranty is good and your project performs well. Infill adds ballast, this makes sure the turf is free from wrinkles and dimensionally stable. It also adds additional protection to the yarn and backing, aides drainage, and ensures a proper footing.

YARN FIBER

Yarn fiber is made of resins made to solve the dual challenges of durability and softness. Fibers come in numerous shades and combinations that allow your eye to see numerous greens. In addition, thatch is often added for even more realism.

Keeping Things Cool with Science

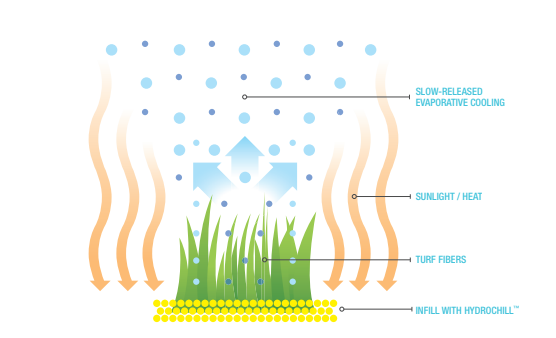

One particular product we love is HydroChill™, our patented evaporative cooling technology.

Perspiration is a natural kind of thermoregulation known as evaporative cooling. Moisture evaporating from the skin’s surface has a cooling effect. HydroChill™ has similarly demonstrated the ability to cool synthetic turf surfaces utilizing the same principle of evaporative cooling. As the turf surface is heated by solar radiation, moisture stored in the HydroChill™ turf is released. As the moisture evaporates, it gives a cooler, more comfortable playing surface.

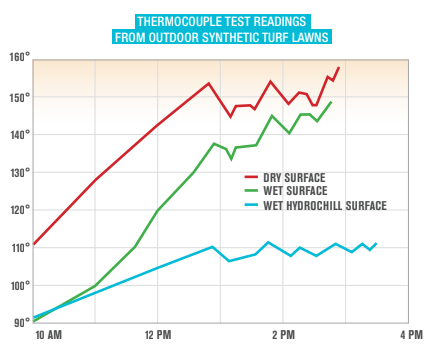

Astandard wet lawn will provide some cooling, but temperatures often rapidly rise and can surpass comfortable levels of heat. A HydroChill™ lawn can create a substantial temperature differential in real-world applications. Based on actual lab and outdoor lawn thermocouple testing, HydroChill™ has achieved 30° to 50° lower surface temperatures compared to a regular synthetic turf system.

Less Work. More Play.

Southwest Greens is not just a product but also a solution. A solution that utilizes much less water each year, significantly reduces the impact on mother nature, and needs far less maintenance. All of which gives you the option of less work, more play.

-1.png?t=1618867322)